23

23

Lab Coat Quality Standard

Definitions

Stain & Damage Defect:

A stain and damage defect is a quality issue related to stains, holes, tears, or other unremedied issues. A defect might be acceptable to some customers, and not acceptable to others. All defects will be identified using a red tie or tag.

Finish Defect:

A finish defect is a quality issue related to wrinkling, unacceptable press creases, missing buttons or snaps. These defects should not leave the plant in this condition.

Escape:

A finish defect that was delivered in an unacceptable status, or a stain and damage defect not identified by the plant using the red twist tie.

Lab Coat Quality Responsibility

Plant Responsibilities:

-

-

-

-

- Inspect all coats as they are hung or pressed

- Stain wash all stained coats one time

- Produce a good quality finish (steam or press)

- Fix or replace missing or broken buttons/snaps

- Identify “stain and damage” defects with a red tie or tag

-

-

-

Service Responsibilities:

-

-

-

-

- Review defective coats identified by the plant

- Understand customer specific quality expectations

- Replace coats as required to satisfy customers

- Communicate escapes to the plant as needed

-

-

-

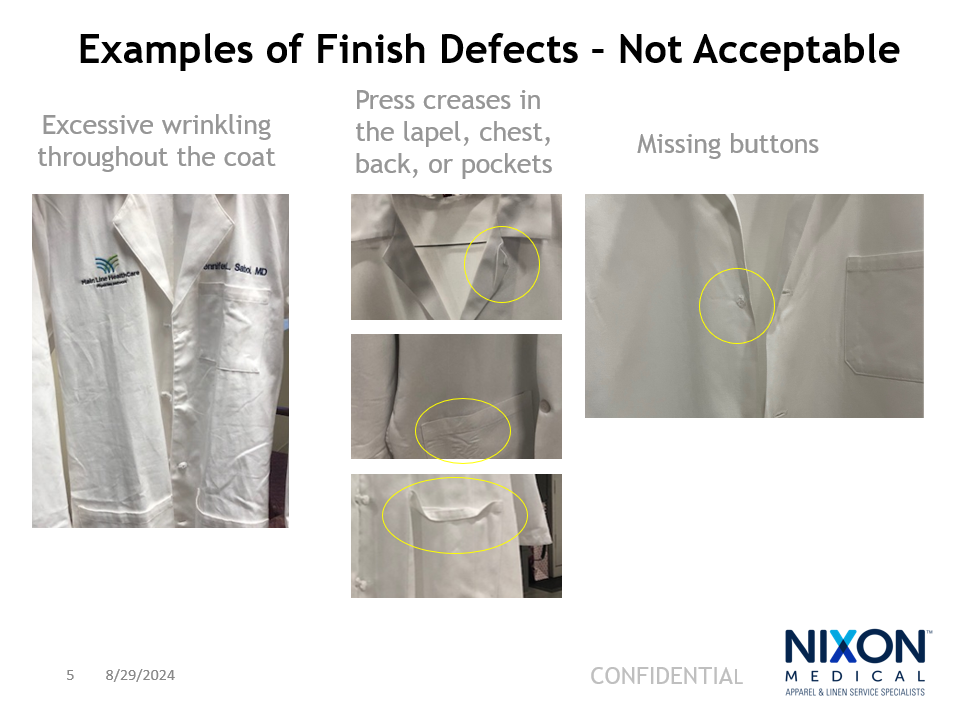

Finish Defects

-

-

-

-

- A missing button or missing snap

- Excessive wrinkling throughout the coat

- Lapels that do not lay against the chest

- Press creases in the lapel, collar, chest, back, or pockets

-

-

-

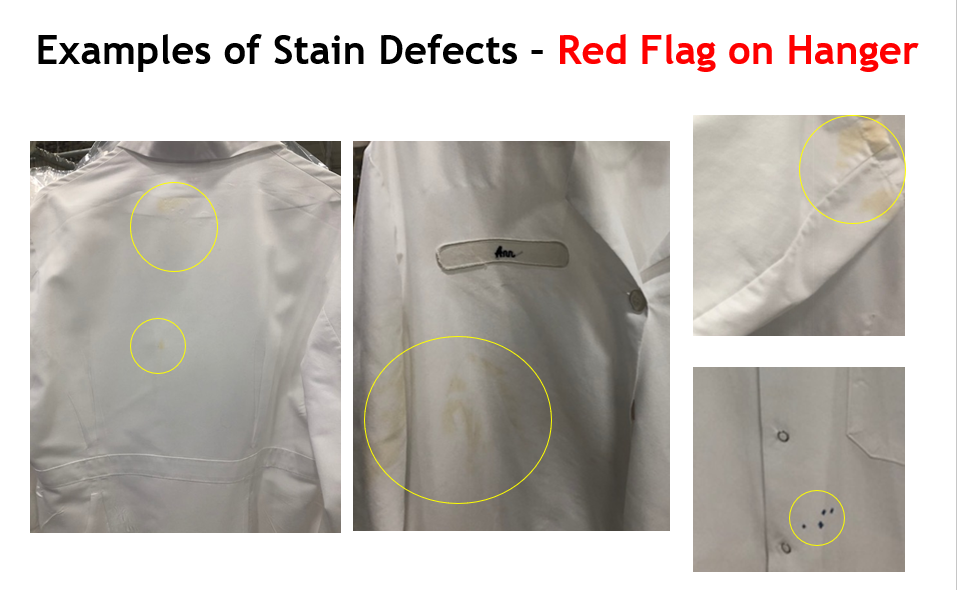

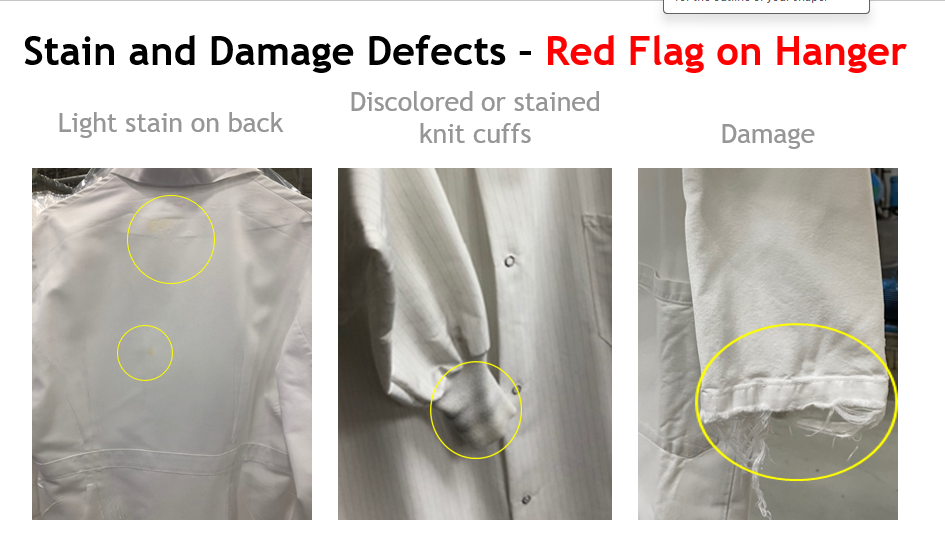

Stain & Damage Defects

-

-

-

-

- Any sized tear or hole anywhere on the coat

- Any light or dark stain anywhere on the coat

- Discolored or stained knit cuffs

-

-

-

Note: Ink stains in pockets clearly made by the customer are considered normal and not a defect.

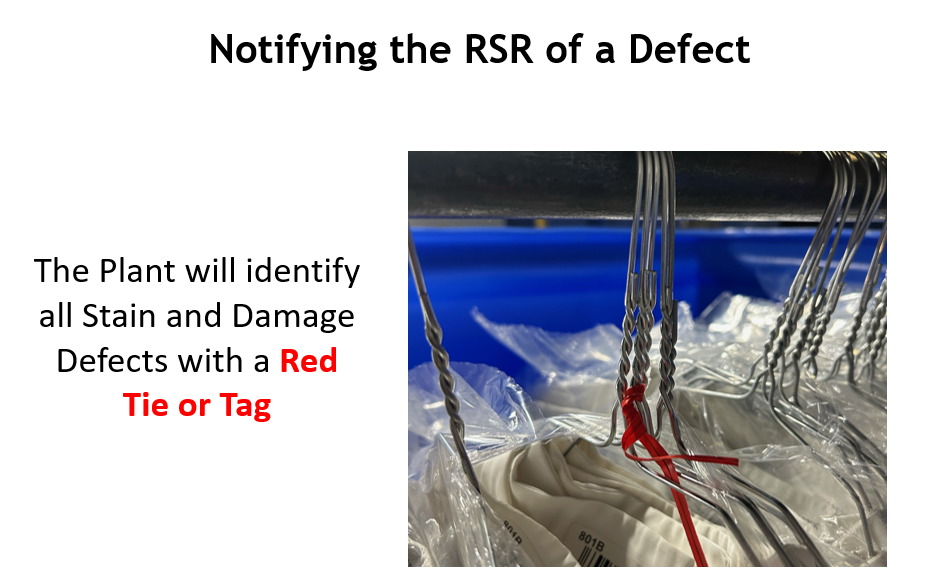

Notifying the RSR of a Defect

The Plant will identify all Stain and Damage Defects with a Red Tie or Tag

Exception for Ink Load Damage

The one exception where we expect the Plant to perform replacements is when an ink pen explodes, causing damage that is unacceptable and irreversible. In these cases, the plant should consider replacement and inform the appropriate service team of this of the replacement(s), using this exception is a local decision