15

15

Objective: The goal of garment inventory management is to ensure the availability of garments for our customers by making them available at the time and in the quality that has been mutually agreed on. By implementing effective inventory control measures, we aim to eliminate shortages, and enhance overall customer satisfaction.

- Location of Team KPI Reports (System): ABS - User Defined Report

- SERVICE-GIM REPORT SCRUBS ROUTE

- SERVICE-GIM REPORT SCRUBS RSD

- Who is Responsible: The responsibility for scrub inventory management lies with the designated Service team. This team, comprised of experienced professionals, will oversee the entire inventory lifecycle, from procurement to distribution, ensuring that optimal levels of garments are maintained, and physical inventories and par level adjustments are made on a quarterly basis.

- Frequency / Due Date: Regular audits and assessments of scrub inventory will be conducted on a quarterly basis by each Route Service Representative. This frequency allows for timely identification of discrepancies and changes in demand. Quick identification enables swift corrective actions. Quarterly physical inventories are scheduled by the Route Service Representative and/or Service Manager and coordinated with the primary facility contact (or service delivery contact) at each customer location.

- Output: The results of the physical inventory are documented in comprehensive ABS reports. These reports help Service Management to set and identify usage patterns, establish recommended par levels, identify replenishment opportunities, and to correct process errors. These reports serve as a tool for internal decision-making and may also be shared with customers, to foster transparency and trust.

- Performance: Completing a garment inventory involves the Route Service Representative utilizing a PDA to scan all clean scrubs at the customer location. Soiled garments are scanned when they are returned to the Nixon Medical Plant location for laundering. Plant locations have barcode scanners built into their processes to capture garment barcodes as they are washed, pressed, folded and prepared for return to the customer. The Metricon conveyor, a modular system designed for the automatic handling of washed garments between laundry workstations, plays a pivotal role in barcode capture and inventory accuracy. Listed below is a link to our Nixon Medical BLR training on how to complete a GIM inventory, internal process and why GIM is important to our customers and our company.

https://nixonmedical.trainingtoday.com/course/7117941/module/12103610?LPId=0

In summary, effective garment inventory management is paramount to meeting customer demands, reducing costs, and maintaining a competitive edge in the market. By adhering to a disciplined process, we can ensure that our customers receive high-quality medical garments in a timely and reliable manner, ultimately enhancing their overall satisfaction with our company.

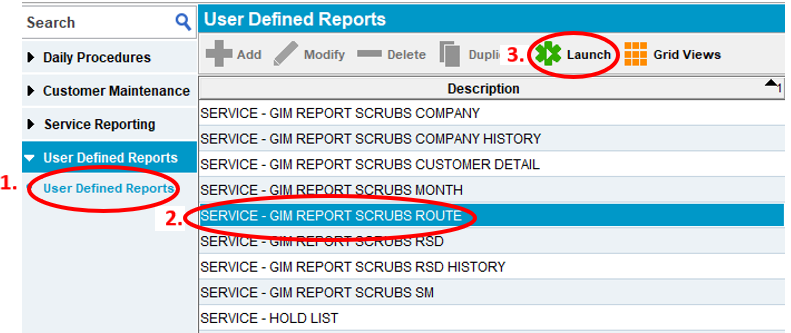

To access the Garment Inventory by Route report:

- Go to ABS User Define Reports

- Select – SERVICE-GIM REPORT SCRUBS ROUTE

- Launch Report

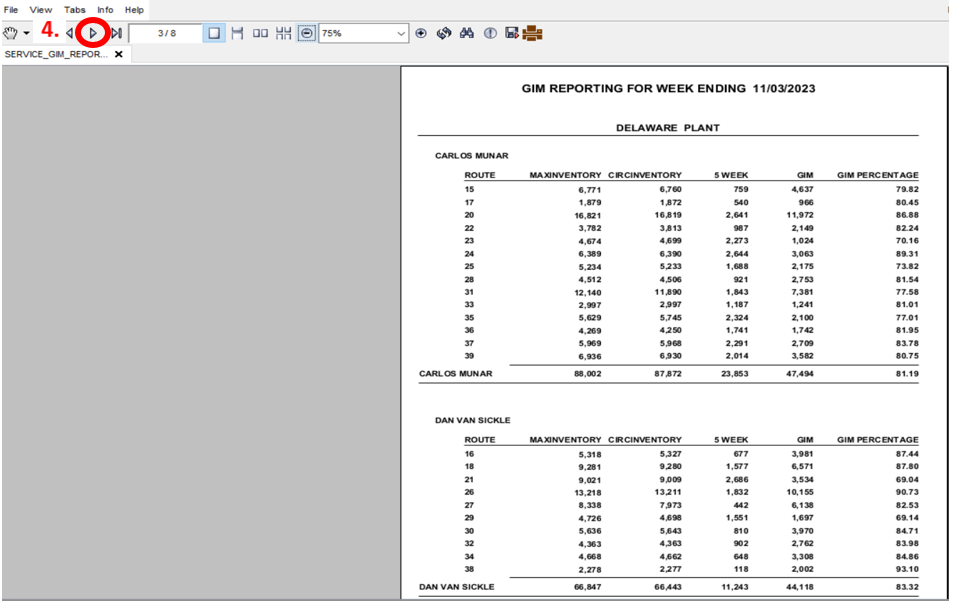

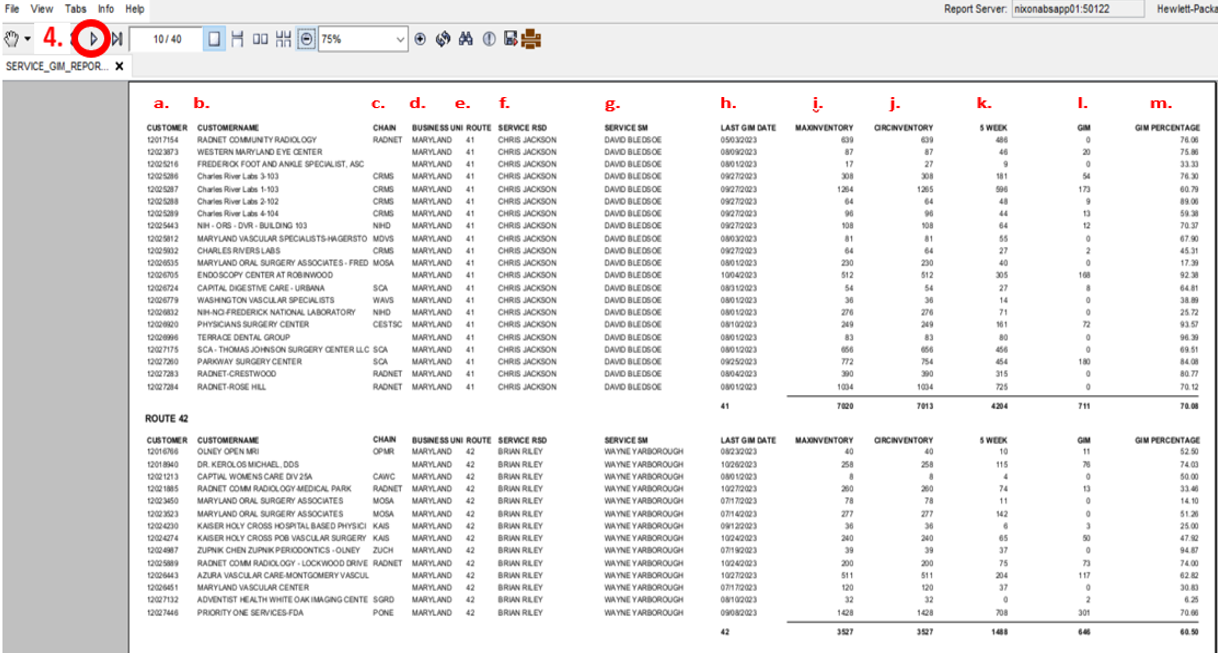

SERVICE-GIM REPORT SCRUBS ROUTE

- Select

until you find your team’s data

until you find your team’s data

-

- Customer Number

- Customer Name

- Chain

- Business Unit

- Route number

- Service RSD

- Service SM

- Last GIM Date – last time garments were scanned using the PDA

- Max Inventory – number of garments assigned to a specific wearer

- Circulating Inventory – number of barcodes in ABS for a specific account

- 5 Week – Metricon scans over the last 5 weeks

- GIM – number of PDA scans during last GIM (rolling 13 weeks)

- GIM Percentage – (GIM + 5 Week) / CIRCINVENTORY

The GIM Report Scrubs Report is used by the Service team to ensure a GIM has been conducted for all accounts comprising a route during the quarter. The report provides a quick view of account GIM status, the last date a GIM was conducted, and snapshots of inventory balances at different points in time. Service Management should run this report weekly to track RSR GIM metric results. Nixon Medical’s goal is for each of our garment accounts to achieve a GIM Percentage of 80% or better.

GIM Percentage = (5 week period scans + GIM scans) / Circulating Inventory

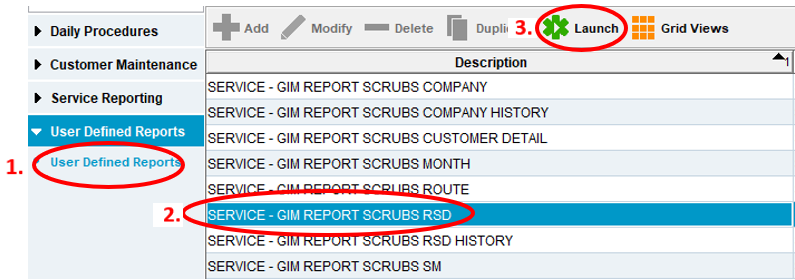

Complete the following steps to access the GIM Report Scrubs by RSD report:

- ABS User Define Reports

- Select – SERVICE-GIM REPORT SCRUBS RSD

- Launch Report

SERVICE-GIM REPORT SCRUBS RSD

Service Management should run this report monthly to view RSR GIM route performance, determine at a high level if MAXINVENTORY and CIRCINVENTORY are aligned by route and if not, research at an account level if adjustments need to be made. Nixon Medical’s goal is for each route to achieve a GIM Percentage of 80% or better. The GIM Report Scrubs RSD will outline each route’s GIM Percentage so the Service team can easily document RSR monthly/quarterly metric results and identify areas for improvement.

- Select

until you find your team’s data

until you find your team’s data