26

26

Objective: The process of increasing garments as customer staff levels change. Route Service Representatives must maintain an accurate wearer inventory to ensure Customer Satisfaction levels remain high.

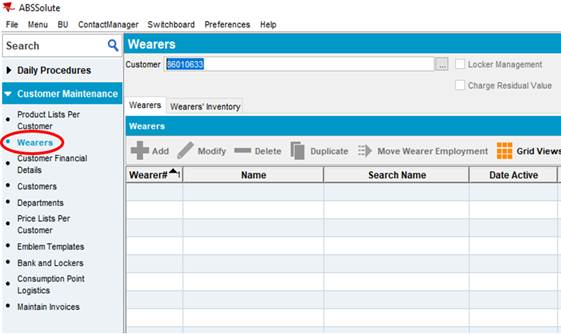

Location in ABS (System): Wearers

Who is Responsible: The responsibility for garment adjustments lies with the Route Service Representatives (RSRs). By properly managing the customer’s garment inventory, customers’ trust and satisfaction (NPS) will improve. If necessary, Service Managers and Regional Service Directors can also make garment adjustments in ABS by completing the following steps:

Complete the following steps to make a garment adjustment:

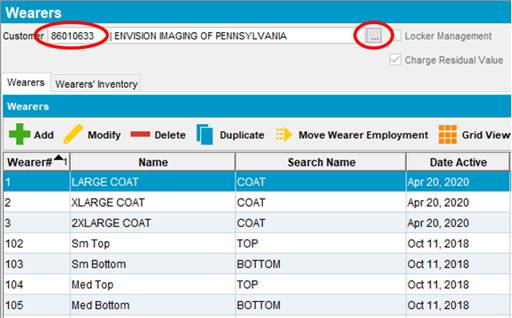

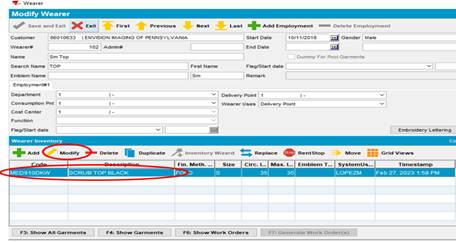

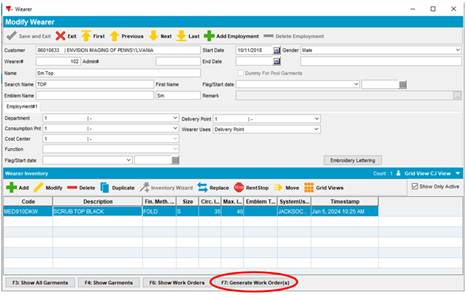

- In ABS, navigate to Customer Maintenance - Wearers

- Increase garment quantities are performed using the Wearer icon

- Enter the eight digit Customer Number or use ellipses (search icon) to locate the desired customer

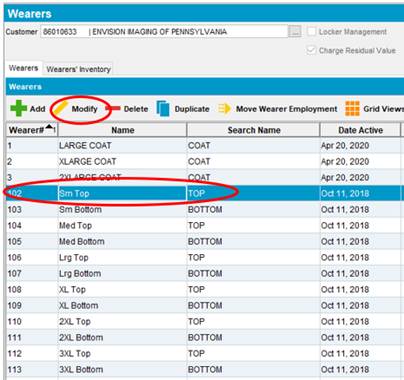

- To increase a wearers garment quantity, select the desired field under Name or Wearer# and select Modify.

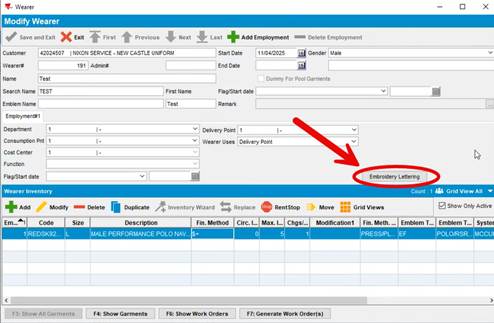

- If embroidery is needed, add the wearers name by selecting Embroidery Lettering

- Manually enter the wearers name and credentials (if needed).

** Do not copy and paste from Excel **

- Select the product you would like to increase under Wearer Inventory and click Modify

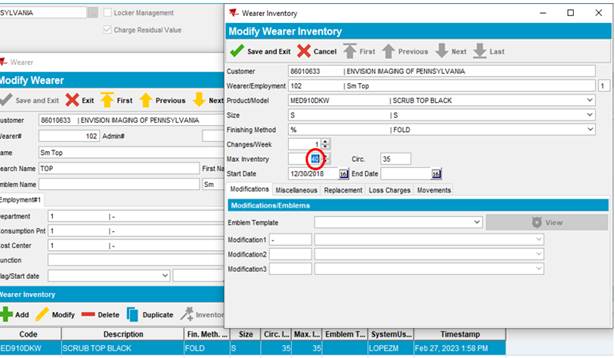

- Update the Max Inventory to include the increased quantity.

- Example: Inventory was set at 35 and the customer would like to increase scrub tops by 5, new Max Inventory should be set at 40

- View the Nixon Medical resource video below for Max Inventory recommendations (https://www.nixonmedical.com/resources/?v=2896).

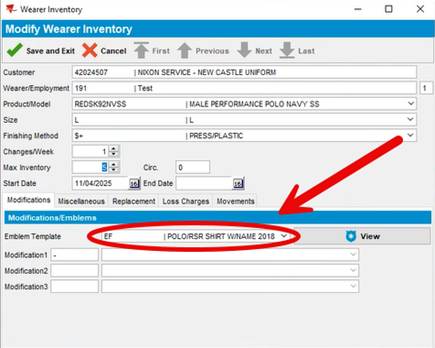

- If the wearer requires embroidery, Select the dropdown and add the emblem template

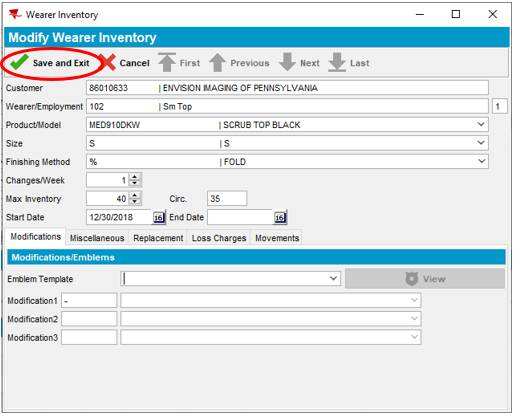

- Select Save and Exit

- Select Generate Work Orders

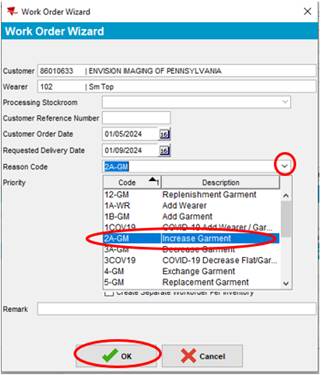

- Select the drop down in the Reason Code field. Select Increase Garment.

- Select Create Separate Workorder Per Inventory

- Select Ok

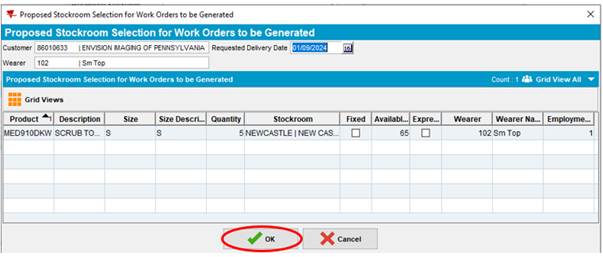

Note: Proposed Stockroom Selection of Work Orders to be Generated pop up window will appear and provides garment availability information to the Service team. This window shows the Product Code, Description, Size, Quantity, Stockroom location and Available Stock in circulation. If Available Stock shows a negative number, requested items may be on backorder and could take up to 4-6 weeks (in some cases longer) to ship and receive.

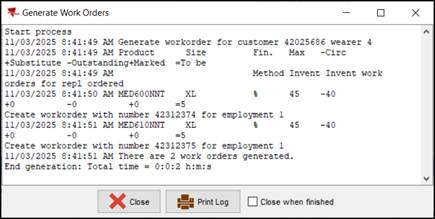

- The work order pop up window will appear to automatically process and send the new work order to the stockroom. Select close once complete.

Note: You do not have to do anything during this process other than closing the window once complete. This process is the ABS system completing the transaction internally and forwarding the information to the appropriate department.