7

7

Objective: The process of removing garments as customer staff levels change and replacing garments due to damage, or wear and tear. Route Service Representatives must maintain an accurate wearer inventory to ensure Customer Satisfaction levels remain high.

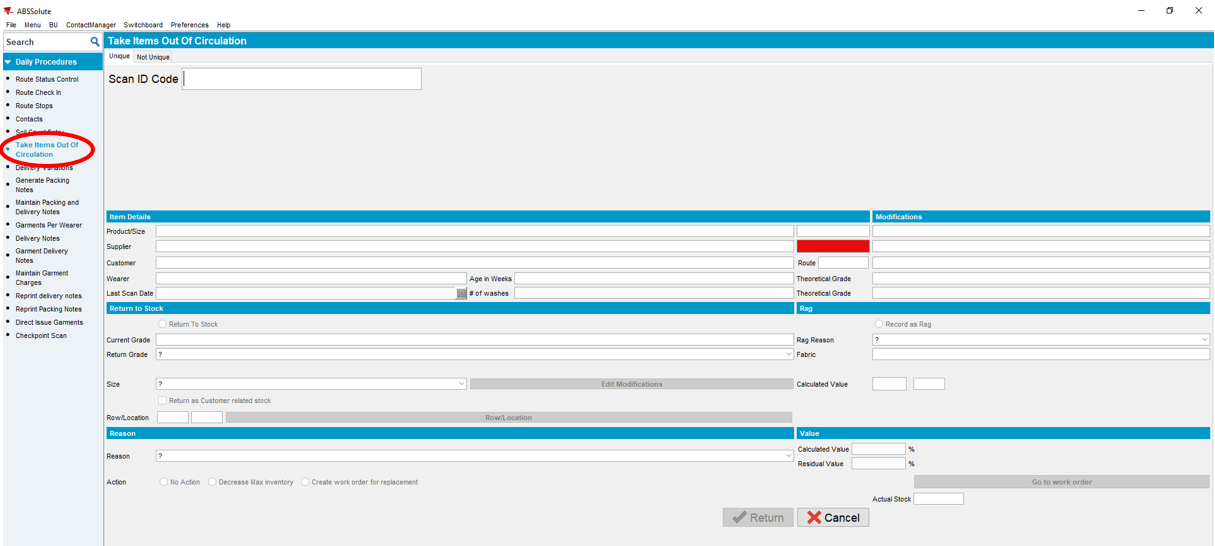

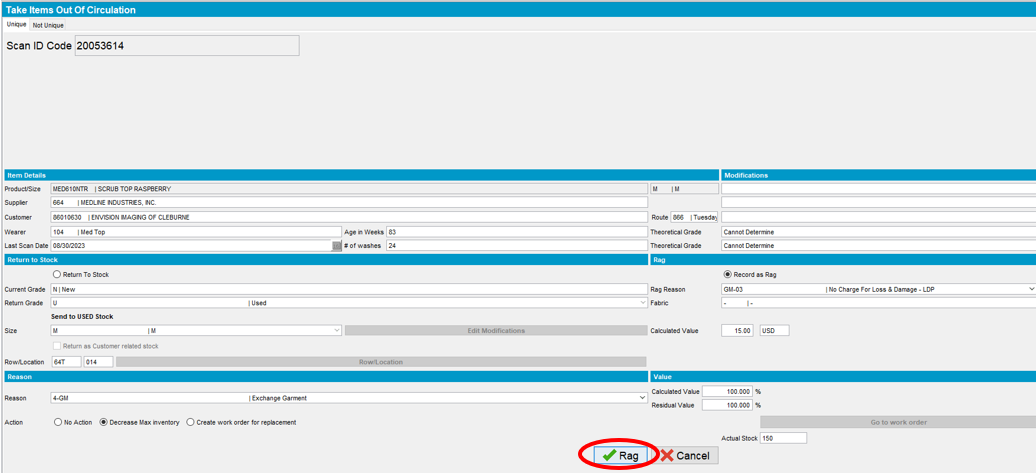

Location in ABS (System): Take Items Out of Circulation

Who is Responsible: The responsibility for garment adjustments lies with the Route Service Representatives (RSRs). By properly managing the customer’s garment inventory, customers’ trust and satisfaction (NPS) will improve. If necessary, Service Managers and Regional Service Directors can also make garment adjustments in ABS by completing the following steps:

Complete the following steps to remove garments from an account:

- In ABS, navigate to Daily Procedures – Take Items Out of Circulation

- Removing and replacing garments are performed using the Take Items Out of Circulation icon

Note: These actions are performed when associates change garment size or no longer work for a company. It is important that you do not start this process until garments are returned to the Route Service Representative. If garments are direct embroidered, then the garments should be scanned and returned back to the customer since they are non-returnable.

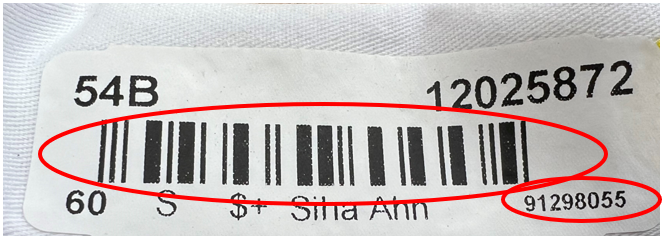

- Scan the barcode on the garment or enter the eight-digit number located on the bottom right of the identification sticker

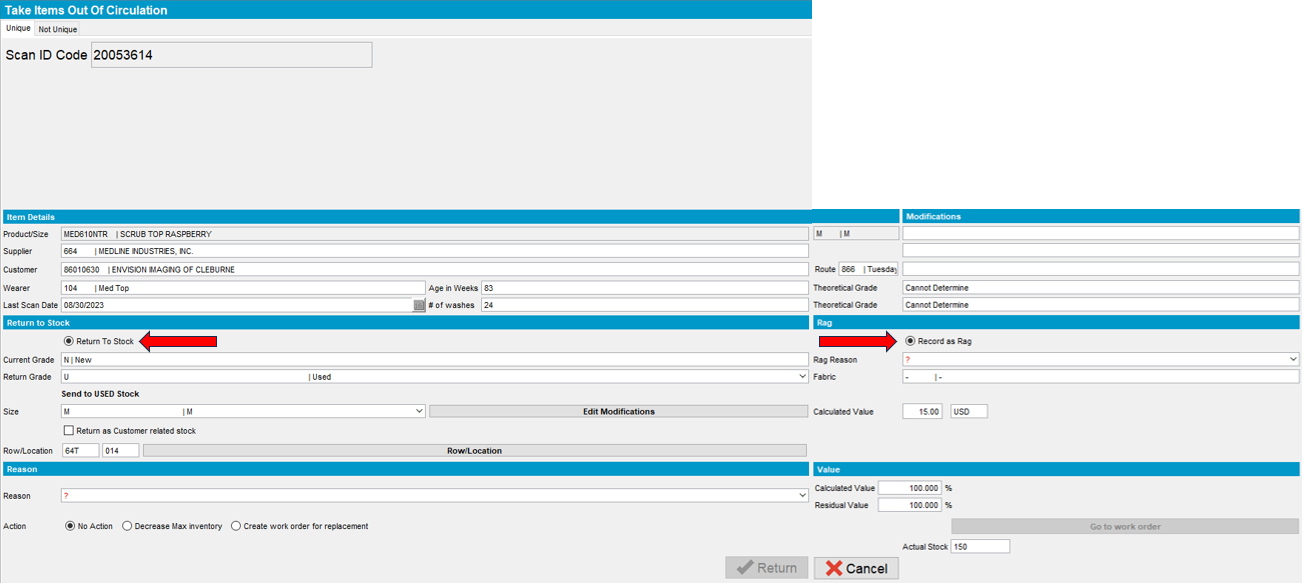

- Select Return To Stock or Record as Rag

Note: Only brand-new garments should be Return To Stock (Stockroom). All other garments should be scanned out using the Record as Rag selection. If garments are blank, then they should be thrown away. If garments are direct embroidered, then they should be returned to the customer.

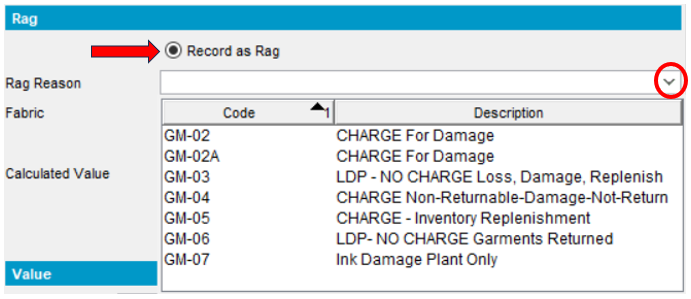

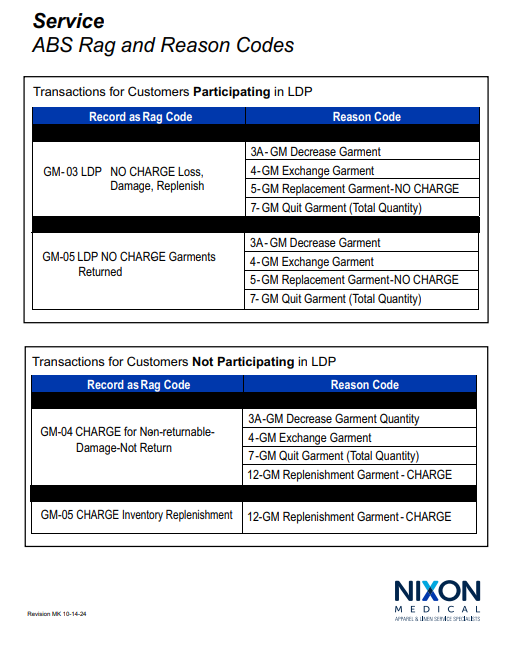

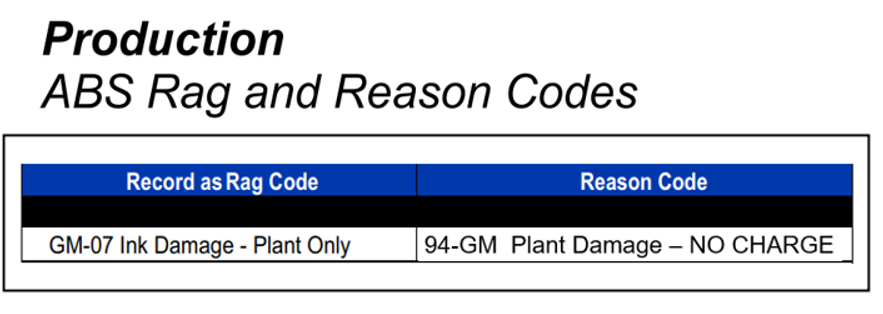

- If you select Record as Rag, then select the dropdown and determine if the customer should be charged for the garment, or if the garment is covered under LDP.

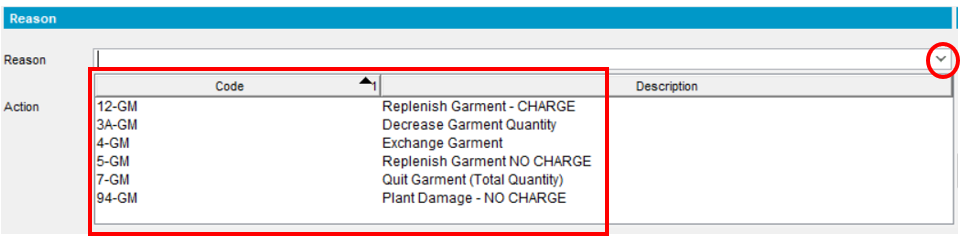

- Select the Reason dropdown and indicate the reason for the change.

The tables below can be used to help select the correct Rag and Reason codes

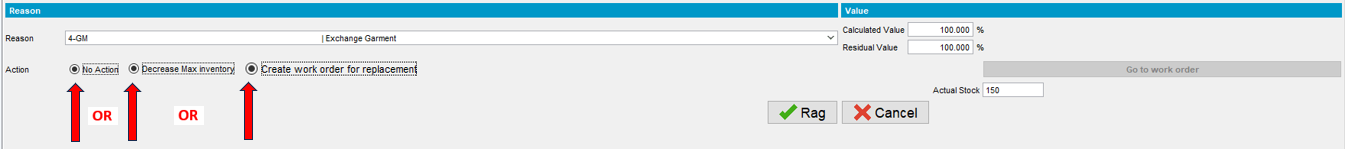

- Select the Action taken in ABS

Note: No Action should only be used when submitting a multiple garment replacement order for a wearer on an account. This action ensures a bulk garment work order is submitted to the stockroom instead of single garment orders. Decrease Max Inventory should be used when garments are being returned from the customer and need to be removed from invoice. Each barcode scanned out will reduce the customers max inventory by one until all garments are returned and max quantity reaches zero. Create work order for replacement should be used when you are replacing a worn or damaged garment for a customer, and only when one garment needs to be replaced for a single wearer.

- Select Rag for each barcode removed or replaced.

-

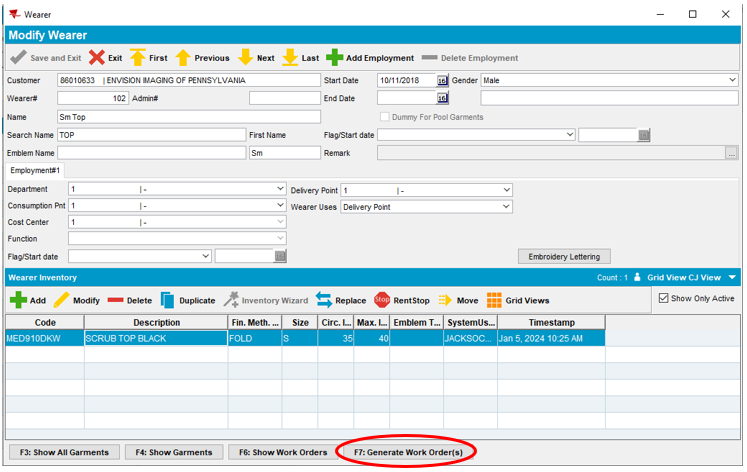

- If you selected No Action, you must go into Wearers and Generate Work Order(s)

-

-

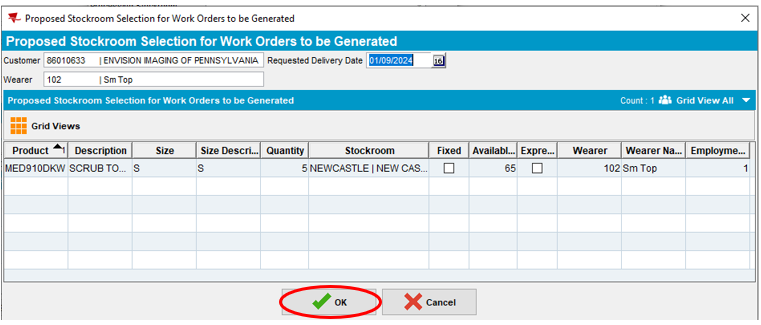

- Select Ok

-

Note: Proposed Stockroom Selection of Work Orders to be Generated pop up window will appear and provides garment availability information to the Service team. This window shows the Product Code, Description, Size, Quantity, Stockroom location and Available Stock in circulation. If Available Stock shows a negative number, requested items may be on backorder and could take up to 4-6 weeks (in some cases longer) to ship and receive.

-

-

- The work order pop up window will appear to automatically process and send the new work order to the stockroom. Select close once complete.

-

Note: You do not have to do anything during this process other than close the window once complete. This process is the ABS system completing the transaction internally and forwarding the information to the appropriate department.